How to prepare the right substrate for oyster mushrooms. Grain mycelium and substrate for growing mushrooms.

When breeding most mushrooms, grain mycelium is used, which is purchased from special farms. To grow mushrooms, the mycelium must be stored under certain conditions, and its quality must be checked before planting. But, even with excellent planting material, one cannot do without special preparation of the substrate - it requires heat treatment and sterilization.

Storing oyster mushroom mycelium, champignons and other mushrooms in the refrigerator

Currently, in cultivation, and mainly vegetative sowing is used with the help of the so-called sterile grain mycelium. It is a boiled and sterilized grain, mastered by the mycelium of a cultivated mushroom cleared of competitors. Non-sterile grain mycelium for growing mushrooms at home is not used, because. in non-sterile conditions, the grain is quickly affected by putrefactive bacteria and mold. Grain mycelium is suitable for the propagation of most fungi. Oyster mushroom and shiitake mycelium is produced on wheat, barley and millet grains, champignon and ringworm mycelium is produced on wheat and rye grains. Grain mycelium for growing mushrooms has a good supply of nutrients. Mycelium produced by a large company, as a rule, guarantees the successful cultivation of the mushroom that is indicated on the package.

Grain mycelium is sold in plastic bags with an air filter containing 8 kg of mycelium. The filter is needed to supply oxygen and to protect the mycelium from molds and other competitors. If stored incorrectly, the mycelium of champignons and most other fungi dies when the air temperature rises above 30 ° C. And at a negative storage temperature, the mycelium freezes and loses its quality.

Long-term storage of mycelium for oyster mushrooms and other mushrooms is permissible at an air temperature of +2 °C. Packages must be stacked with air gaps, as mycelium is heated as a result of its own vital activity. At home, storage of grain mycelium is possible in a household refrigerator, but not in a freezer. It must be borne in mind that although mycelium can be stored in modern household refrigerators, it must be taken into account that in a chamber with automatic defrosting, the temperature periodically fluctuates from +1 to +10 °C. Therefore, when long term storage of oyster mushroom and shiitake mycelium inside the bag, a hard crust of mycelium and the rudiments of fruiting bodies are formed, and mycelium of champignon and ringworm quickly deteriorates.

When buying mycelium in small packages, you need to make sure that there is an air filter or holes in the bag for air. Without this, the mycelium will quickly rot, and with holes without a filter, sooner or later it will become infected with mold.

Even if you have complied with all the conditions for storing mushroom mycelium, you need to check its quality before planting. You can do this in the following way. Prepare a solution of a teaspoon of sugar in a glass of boiled water. Fold the toilet paper in several layers into a 5x5 cm square. Clean toilet paper is sterile, unlike napkins. Moisten a paper square liberally with the sugar solution, wring it out and place it in a Petri dish or on a clean saucer. Place a few grains of grain mycelium from a purchased bag and cover with a lid of a Petri dish or a glass. At room temperature a week later, on the grains or on another substrate sold to you as mycelium, a white edge from the mycelium growing in the air should appear. There should be no colored spots. This sprouted mycelium should not have mold spots even a few months later. So you can check not only grain, but also any other mycelium.

Reproduction of oyster mushroom mycelium and other mushrooms at home

Purchased high-quality mycelium can be propagated independently. For the reproduction of mycelium of fungi, wheat grain must be boiled over low heat for 20-25 minutes. It cannot be digested. It is important that the core of the grain remains white. Then the grain must be dried on the table, stirring it with a spatula for 30 minutes. Can be dried under a fan. After that, it should have a moisture content of 50-53%. For drying, chalk and gypsum can be added to the grain - 5% by weight of the grain. The grain prepared in this way is poured into two-liter glass jars at the rate of 1 kg per can. Grain when propagating oyster mushroom mycelium at home should occupy less than half the volume of the jar. Jars with grain are tightly closed with lids with a stopper made of sterile cotton wool and sterilized together with grain in a pot of boiling water or in an autoclave. For a cork, a hole with a diameter of 3 cm is made in the center of the lid. To prevent boiling water from wetting the cotton plug, wrap the lids with aluminum foil or kraft paper, which you tie around the neck of the jar with twine. Trim off the excess paper.

When propagating mycelium, put a rag under the jars and pour cold water 3-4 cm below the lids. To sterilize the grain, the jars must be boiled twice for 2 hours with an interval of a day. In the interval between boiling, the jars should be at room temperature. When using an autoclave at a temperature of +120 °C and an overpressure of 1.0 atm. it is enough to sterilize once for 2.5 hours. Sterilization in a domestic autoclave at +110 °C is acceptable.

Without removing the lids, the jars with grain must be cooled to +22 ... +55 ° С and transferred to a sterile box or to another clean room for sowing grain with sterile mycelium at your disposal. During sowing (inoculation), the lid with the filter must be removed, put a tablespoon of mycelium in the jar and again close the lid with a cotton plug, then kraft paper and tie. Then the jars should be shaken to evenly mix the mycelium with the grain and put in a clean room with an air temperature of +24 ... +26 ° C for overgrowing.

The incubation time in a jar of grains is 14 days for the propagation of oyster mushroom mycelium, and more than 30 days for shiitake. The duration of incubation of other fungi takes the same period. After 7 days of growing the mycelium, the contents of the jars should be shaken so that the grain is not too strongly held together by the mycelium, and the overgrowth of the grain is uniform.

After the grain in the jars is completely overgrown, you can transfer the mycelium from the jars to plastic bags.

Substrate for growing oyster mushrooms and other mushrooms

Good yields of oyster mushrooms, shiitake and others tree mushrooms can be grown on a loose substrate made from chopped straw, cotton linters, sunflower seed husks or ground branches. Nutrient additives can be added to such a substrate for growing mushrooms, and heat treatment of the substrate will free it from molds. The granular structure provides oxygen access to the developing mycelium, so the development of such a substrate is several times faster than the development of dense wood. To create a high concentration of carbon dioxide, necessary for the growth of mycelium, the substrate at home is placed in plastic bags with air-permeable stoppers or perforations.

The basis of the substrate is the material that makes up more than 50% of its total mass. The nitrogen content in the main materials of the substrate is as follows: sawdust - 0.1%, flax fire - 0.5%, straw - 0.6%, husk - 0.7%, cotton linters - 0.7%, ground branches - 0 .7% (all based on dry weight). To achieve the optimal nitrogen content (0.7-1.0%), the substrate for mushrooms can be made grain by adding grain or bran to it in an amount of 10-20% of the dry weight of the substrate. The substrate must be moistened so that its moisture content is in the range from 45 to 70%. The optimum moisture content of the substrate is 60%.

The moisture content of the substrate for mushrooms (W%) is the ratio of the mass of water in it to the mass of the substrate, expressed as a percentage. Humidity is determined as follows: 100 g of the substrate is kept in an oven or oven for 6 hours (up to constant weight) at a temperature of +110 ... +120 ° C (not higher than 150 ° C to prevent charring of the dried components).

The difference between the weight of the wet and dry sample, expressed in grams, will be numerically equal to the moisture content of the substrate in percent. You can dry a 100 g sample in microwave oven instead of a dryer. The microwave oven is set to 350-400 watts. Warm-up mode: warm-up 4 min; pause 2 min; warm-up 4 min; pause 2 min; warm-up 4 min.

Mushrooms- aerobic organisms that consume oxygen from the air and release carbon dioxide. Therefore, the main parameter of the substrate base for fungal mycelium is its air permeability: the structure of the substrate must be loose, and the shell of the substrate block (polyethylene bag) must have a hole for the mycelium to “breathe”. The air permeability of a wet substrate sharply decreases with a decrease in the particle size of the substrate base and, especially, when the substrate is waterlogged, when zones filled with free water appear in it. The diffusion coefficient of oxygen in water is tens of thousands of times less than in air. Therefore, waterlogging of the substrate for oyster mushrooms and other fungi creates anaerobic conditions in it, in which the mycelium cannot exist.

Processing when preparing a substrate for mushrooms at home

The best material for future substrate mycelium is small chips from ground fresh hardwood branches. If you cannot use all the harvested raw materials at once, you need to grind the branches and then dry them at high temperature in an oven or oven. From 1000 g of fresh branches, 500-600 g of dry ones will be obtained. Instead of ground branches, you can use chopped straw that has not been exposed to rain, flax bonfire or husk from sunflower seeds. The next step is to prepare the required amount of pure three-liter jars. Make a round hole 1-2 cm in diameter in plastic jar lids. Wash lids and jars thoroughly. Firmly insert sterile cotton plugs (twisted pieces of cotton wool) into the holes of the lids. During the heat treatment of the jars, remove the lids with corks in a clean plastic bag.

The best material for future substrate mycelium is small chips from ground fresh hardwood branches. If you cannot use all the harvested raw materials at once, you need to grind the branches and then dry them at high temperature in an oven or oven. From 1000 g of fresh branches, 500-600 g of dry ones will be obtained. Instead of ground branches, you can use chopped straw that has not been exposed to rain, flax bonfire or husk from sunflower seeds. The next step is to prepare the required amount of pure three-liter jars. Make a round hole 1-2 cm in diameter in plastic jar lids. Wash lids and jars thoroughly. Firmly insert sterile cotton plugs (twisted pieces of cotton wool) into the holes of the lids. During the heat treatment of the jars, remove the lids with corks in a clean plastic bag.

After preparing the substrate in the amount needed to fill one or more three-liter containers, transfer it to jars. Compact the substrate so that it does not reach the neck of a few centimeters. Pour boiling water over the substrate in the jar so that the jar does not burst. After soaking, add boiling water so that it completely covers the substrate. Close jars with lids with holes for draining water, but do not immediately drain the water. Leave the jars of boiling water to cool slowly at room temperature for 2-3 hours. Turn the jars over, drain the water from them and leave them upside down for a day. During this time, the water will drain from the cans, and the undead mold spores in the substrate will germinate and become defenseless against a second rise in temperature. This method is called the fractional substrate pasteurization method.

In the process of preparing the substrate at home, weigh each jar of moistened contents on a scale. To heat the substrate for oyster mushrooms and other mushrooms, cover the jars with aluminum foil or tin lid(leaky). Put the jars in any thermal oven or oven for 3 hours at a temperature of 80 ° C.

Let the jar cool to room temperature and weigh it again. If the substrate jar lost more than 20% in weight during the heat treatment, bring the jar to 80% of its original weight by adding boiled water to the substrate. Remove the aluminum foil and close the jar with a clean plastic lid with a cotton stopper. Now the substrate is ready for sowing it with mycelium.

A simpler method of heat treatment of the substrate is called xerothermic. This is followed by the preparation of the substrate soaked to the desired moisture content in the amount necessary to fill one or more three-liter jars. Put it in banks.

Compact the substrate so that it does not reach the neck - a few centimeters. Weigh the substrate jars. Put the jars in the oven, heated to a temperature of 110 ° C for 2-4 hours, so that all the water from the substrate boils away, cool the jars and pour clean water into the substrate. boiled water in such an amount as to restore the weight of the substrate, which was before heat treatment. Close the jar with a clean plastic lid with a cotton stopper. Now the substrate is ready for sowing it with mycelium.

Processing the substrate of oyster mushrooms and other mushrooms in the garden

With clean, mold-free raw materials, pasteurization can be carried out only once. In the garden, you can pasteurize the substrate in a 200-liter barrel on a fire. Place the barrel on concrete blocks or bricks. Pour 50 liters of water into it. Above the water, on bricks placed vertically inside the barrel, insert a round (barrel-shaped) grid or grate.

With clean, mold-free raw materials, pasteurization can be carried out only once. In the garden, you can pasteurize the substrate in a 200-liter barrel on a fire. Place the barrel on concrete blocks or bricks. Pour 50 liters of water into it. Above the water, on bricks placed vertically inside the barrel, insert a round (barrel-shaped) grid or grate.

After preparing the substrate for mushrooms of the desired composition and the desired humidity, fill polypropylene bags with it, leaving part of the bag empty for tying its throat with a rope. You can use "rustling" polyethylene bags low pressure. More flexible polyethylene bags high pressure that do not rustle are not suitable for this. They will break down when boiled. More expensive freezer bags are also suitable. Insert a piece of cotton wool or padding polyester into the neck of the bag as a breathable stopper. Pull the string around the neck of the bag around the cork. Place the substrate blocks in several tiers on the grid upside down. Close the barrel with a lid and leave the barrel with the substrate for a day or more for mold spores to germinate in the substrate. The next day, light a fire under the barrel and boil water for 6 hours in a row. By the next morning, the substrate in the barrel will cool down. To “seed” the substrate, untie the bag, remove the cork, check that the temperature of the substrate is below 30 ° C, add mycelium, then reinsert the cork and tighten the neck of the bag with twine.

When growing exotic mushrooms(shiitake, maitake) for greater reliability, it is necessary to carry out a double fractional pasteurization. The sequence of operations for double fractional pasteurization is as follows. Bags with a substrate soaked to the desired humidity, closed with a synthetic winterizer or cotton plug, kept at room temperature for a day, then placed in a "Chinese barrel" on a fire, pasteurized at a temperature of +80 ... +100 ° C for 3-6 hours, depending on the volume of the bag. After that, they are left in the barrel to cool for 16-24 hours, then the fire is kindled again and the second pasteurization is carried out.

In the same way, pasteurization can be carried out in a sauna or in any other bath at +80…+90 °C.

Substrate preparation for oyster mushrooms and other fungi: sterilization

The basis of any autoclave is a strong container with a lid that can withstand excess pressure of water vapor inside and is equipped with a valve to bleed the steam in case of a dangerous excess of pressure. It is believed that when preparing a substrate for oyster mushrooms and other fungi in an autoclave, complete sterility is achieved at +134 ° C - all organisms known on earth die. Microorganisms that can harm cultivated mushrooms die at +120 °C. Industrial autoclaves designed for mushroom growing operate at an overpressure of 1 atm, which ensures that the substrate is treated at +120 ° C with “fluid steam”. This allows you to completely sterilize the fungal substrate.

A few words about what "flowing steam" processing is. From the steam generator, steam is supplied to the autoclave tank, where the substrate is located in open containers or in leaky sealed bags. It is possible to periodically release part of the steam, ensuring that new portions of it enter the autoclave. This treatment of the wet substrate ensures complete sterilization. In this case, all areas of the substrate are treated with steam, and not with dry air. This is very important, since dry spores of some molds and bacteria remain viable at a temperature of +160 °C.

Currently, online stores offer various options household autoclaves designed for sterilization of canned food at home. They are similar to our "Chinese barrel" on the fire, but they work with high blood pressure steam, ensuring the processing of canned food or, in our case, the substrate at a temperature of +110 ° C. Substrate bags or jars are placed inside a domestic autoclave on a grate over boiling water. This is not a “flowing steam” treatment and not a complete sterilization of the substrate, but such a treatment is quite sufficient for growing any mushrooms in a home garden.

The selected substrate must be mixed in a basin with additives, if any, and with water in the amount necessary to reach the substrate. required humidity. Transfer the substrate into bags. Close the bags with cotton or padding stoppers and place in an autoclave. Even better, just put open bags of substrate in the autoclave and put cotton plugs and twine leaky wrapped in aluminum foil there.

Close the lid of the autoclave, set the automation to the desired temperature and processing time, and follow the instructions attached to the autoclave. The presence of automatic control of the autoclave operation allows you to fill it and turn it on in the evening, and in the morning to get bags with a cooled substrate out of the autoclave and sow the substrate with mycelium. When manually operating the autoclave, before turning it on, make sure that there is water in it and control its operation, focusing on the thermometer readings.

Oyster mushrooms are in high demand among buyers, a huge number of them are sold through the distribution network. But few summer residents know that growing oyster mushrooms at home is a troublesome business, but quite possible. There are several ways to grow this mushroom, they will allow you to get a rich harvest throughout the entire summer-autumn period, and even all year round. In addition to the natural method of growing oyster mushrooms on wooden chocks, there is a method of growing on straw or a mixture of straw and sawdust.

Growing oyster mushrooms on stumps

The easiest way to get oyster mushrooms at home is to grow on stumps obtained by sawing deciduous trees, conifers are not suitable for this. Grain mycelium with a layer of a couple of centimeters is applied to a fresh cut, covered with polyethylene, sprinkled with earth. Best time for sowing - early April. For sowing one hemp, about 100 grams of mycelium will be required. The second method of sowing involves the introduction of mycelium into the cuts on the stumps or holes drilled in them. After making the mycelium, they are covered with sawdust. Sections of stumps are covered with polyethylene and covered with soil.

The process of development of the fungus lasts from 3 to 4 months, at the end of September it will be possible to harvest. Before the start of fruiting, from the middle of the month, the soil and the film from the stumps are removed. It should not be forgotten that the growth of mushrooms requires high humidity and a nutrient medium, so the soil around the stumps should be watered several times a week.

Growing oyster mushrooms in the garden

how to prepare a substrate for growing oyster mushrooms

For growing mushrooms of this species, you can use not only hemp or wooden chocks - the use of a straw substrate makes it possible to speed up the process of obtaining a crop and even helps to increase it. In addition, during its preparation there is no need for heat treatment, and the period of possible cultivation of mushrooms in it reaches two years.

To prepare the substrate, you can use a mix of their sawdust and straw, best of all rapeseed, pea, wheat. Only fully matured and thoroughly chopped straw should be used. It should be borne in mind that in order to prevent infection of the mycelium with mold, it is desirable to subject the straw not only to moisture, but also to fermentation without air access.

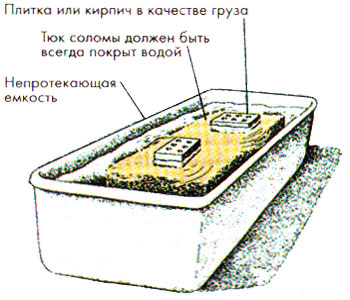

Straw is fermented as follows: it is placed in a container with water, pressed down with a load and kept for 2 to 3 weeks, depending on the temperature. It is undesirable for the temperature to drop to +10 or fall even lower - the fermentation process will slow down greatly. During the fermentation process, water should be added to the container as needed.

The ongoing fermentation will lead to the creation of an acidic environment that the oyster mushroom loves and does not tolerate fungal bacteria very well. After processing, the color of the straw will become lighter, it will acquire a characteristic sour smell.

Next, the straw must be removed from the vat and laid out in such a way that glass from it excess water, it will take days. Next, the straw is mixed with sawdust of hardwood, best of all - beech, in the proportion: 6 parts of straw to 7 parts of sawdust. Chalk is added to the mixture - 3% of the total weight and urea, not more than 0.5%. It is not recommended to exceed this amount - the yield may decrease significantly. If alfalfa or pea straw is used, then the addition of ammonium-potassium nitrate is allowed, also not more than 0.5%. When using wheat or rapeseed straw maximum amount mineral fertilizers is calculated from the weight of the dry mixture and is not more than 0.8%, urea can be used half as much.

creation of beds for growing mushrooms

Further, the technology of growing oyster mushrooms involves the creation of beds. They lay it as follows: they dig a trench 20 cm deep and up to 1 m wide, a formwork slightly expanded downwards is assembled in it, its dimensions are: 30x100x20 cm. The substrate is tightly laid in the resulting wooden form, it is pressed. After removing the mold, a block for oyster mushrooms should remain with an area of \u200b\u200babout 0.3 sq.m and a height of 18-20 cm. The blocks in the trench are laid side by side, with a gap of 15 cm. It is covered with soil, but the surface of the blocks cannot be allowed to be contaminated. Experienced mushroom pickers recommend, in order to increase productivity, to lay slices of beech branches 2 cm thick and up to 7-8 cm in diameter in the upper layer of the substrate.

how to lay oyster mushroom mycelium

To begin with, it should be noted that it is not recommended to store oyster mushroom mycelium for a long time, it is advisable to buy it no more than a couple of weeks before the planned planting. The laying of the mycelium is carried out to a depth of 3-4 cm; for laying one square meter of the mycelium area, it will take from 1 to 2 liters. Pawned pieces must be of the appropriate size chicken egg placed them at the same distance. The sown beds are covered with foil, then with boards.

The beds are laid in August, they should be covered until the third decade of September. Next, you need to remove it, and surround the beds with a structure of boards up to 15 cm high. Direct sunlight should not fall on the beds, for this a canopy is built over them.

The first fruits can be obtained in early October, the duration of fruiting depends on weather conditions. Harvest as oyster mushrooms grow. When fruiting is over, the beds are left in the same state until spring. The only care measure can be watering the beds in case of severe drying of the soil.

With the onset of spring or autumn of the next year, fruiting may be restored, but the yield of oyster mushrooms will already be lower.

Judging by the results obtained by experienced mushroom pickers, it can be argued that the best option the substrate is a mixture of rapeseed straw and beech sawdust, it practically does not suffer from the development of molds that prevent the development of oyster mushrooms.

Preliminary cultivation of mycelium in boxes is considered to be an effective measure: they are placed in a room with a controlled temperature, which allows for a more complete colonization of the substrate by mycelium. The boxes used for the growth of mycelium should have an area equal to 0.5 sq.m and a height of 0.2 m. At an indoor temperature of about 22-25 degrees, the process will last from 3 to 4 months. To make it easier to remove the substrate from the boxes, their bottom is lined with foil. Blocks of oyster mushrooms after turning out of the boxes are used to form open ground beds.

Also, for growing oyster mushrooms in the country, you can use straw bales without adding sawdust, they are fermented, then urea and nitrate are added.

This method of growing oyster mushrooms at home is called extensive. There is another, more expensive intensive method of growing in special lighted rooms, the main advantage of which is high yield.

Intensive method of growing oyster mushrooms throughout the year

Under such conditions, it is rational to use a substrate that can be colonized by mycelium in the shortest possible period: wheat straw, corn stalks, reeds. In nature, fungi cannot grow on such materials - it is difficult for them to compete with microorganisms and mold. Therefore, it will be necessary to slow down the development of harmful microorganisms by artificial means:

- by sterilizing the nutrient medium by heating and continuing to grow under sterile conditions - a complex, expensive, but reliable option;

- by initially sterilizing the substrate and growing in non-sterile conditions - a more affordable option popular with mushroom growers.

substrate preparation

It is the second method that can be considered in more detail and used in the practice of growing mushrooms in a suburban area. The substrate is prepared from peeled corn cobs and chopped straw, avoiding the ingress of rotten material. 2-3% limestone flour is added to the mixture. Next, the substrate is moistened, about 120 liters of water should be used per 1 centner of ground cobs. It will be necessary to achieve by mixing a uniform strong wetting of the material - when pressing any sample taken, water should drip.

Next, the substrate is subjected to heat treatment, if possible - steaming. At a temperature of about +55 +60 C, it must be kept for 12 hours. Small containers can be sterilized in an autoclave.

If it is not possible to use steam, it is possible to provoke a natural heating of the substrate - it is trampled into boxes, put in a pile and wrapped in foil for 8 days. The heating of the material can also be carried out in a bath with hot water- bags with a substrate are placed in it for 12 hours. In addition to sterilization, heating improves the structure of the material.

sowing mycelium

At the preliminary stage, at a temperature of +16 to +27 C, the prepared nutrient mixture is packaged in boxes or bags, the weight of each container is from 5 to 15 kg. After lowering the temperature of the mixture to +30 C, inoculation is carried out, i.e. mix the oyster mushroom mycelium with the substrate or lay it out in a thin layer on the surface. It is possible to lay lumps of oyster mushroom mycelium in nests. The amount of seeded mycelium is up to 5% of the total mass of the moistened substrate.

If oyster mushrooms are grown in plastic bags, then cuts are made in them at a distance of 12-15 cm through which mushroom bodies will come out during the fruiting period.

preparation period

An important condition for the proper cultivation of oyster mushrooms is to maintain perfect cleanliness in the room. The air humidity should be 90%, but it is not allowed to directly wet the substrate. The temperature required for the development of mycelium is within +25 +27 C. If an increase in temperature is detected during measurement, the room should be well ventilated.

How well the sowing was done will become apparent fairly quickly, after about 10-12 days numerous hyphae fibers will appear. Be sure to check the substrate for the presence of moldy areas of a greenish or bluish tint - they must be removed.

After the substrate has cooled down, the indoor temperature is lowered to +20 C. Lighting is not required at this stage of cultivation. In the process of mushroom ripening, it will be necessary to maintain the temperature within +22 C; direct watering of the substrate is undesirable. to maintain the humidity of the air should be watering the walls of the room. This period lasts about 3 weeks.

features of caring for oyster mushrooms during fruiting

The upcoming fruiting period will require:

- convenient arrangement of oyster mushroom blocks,

- maintaining the temperature within +16 C,

- air humidity about 90-95%

- high-quality ventilation of the room, but without drafts,

- illumination for at least 10 hours a day.

Regarding lighting, it should be noted that its norm is determined in each particular case separately, the goal being pursued is to obtain a normal fruiting body of the fungus, in which the length of the mushroom stem is half the diameter of its cap. The growing mushroom should be illuminated from above, in which case its leg will not stretch too much. Excessive stretching of the leg can be observed in the absence of proper ventilation. You can place bags with growing oyster mushrooms only on the floor or racks, but do not create "multi-storey structures" at the same time - in this case, lighting will not work correctly.

harvesting

Oyster mushrooms are harvested when their caps reach the optimal size. Oyster mushrooms should be cut with a thin, very sharp knife, put in a prepared container. A good harvest is considered to be about 25% by weight of the weight of the dry substrate. Ideally maintained growing conditions can lead to a yield increase of 10%.

Since in the first wave of fruiting oyster mushroom usually gives up to 75% of the potential yield, then experienced mushroom pickers prefer to start the next growing cycle.

Diseases and pests of oyster mushrooms

Usually there are no problems with pests or diseases during the first rotation, flies or fungus gnats may appear during repeated cultivation.

With poor-quality heating of the nutrient mixture, the appearance of a weed-dung fungus can be observed. Its spores are not always killed by exposure elevated temperature environment. Any plant that appears that differs from typical oyster mushrooms, such as excessive fragility of the stalk or a bright separation of the stalk and cap, should be destroyed.

Mold fungi can cause significant yield losses - to prevent the disease, it is necessary to carry out high-quality processing of the substrate and disinfection of the room before each new laying.

Oyster mushroom is a fungus that can use the cellulose and lignin contained in the substrate for its development. In addition to carbohydrates, oyster mushroom needs proteins and fats for the full development (Tables 1, 2).

Table 1

Mushroom cultivation: oyster mushroom, champignon, shiitake

Spectacular emergence of mushrooms. As you know, mushrooms grow quite quickly, especially after rain. Watching this process in slow motion is incredibly interesting.

table 2

| substrate | Protein | Fats | Cellulose | Ca | P | N | K |

| alfalfa hay | 14,8 | 2 | 28,9 | 1,5 | 0,2 | 2,4 | 2 |

| Alfalfa leaf flour | 21,2 | 2,8 | 16,6 | 1,7 | 0,2 | 3,4 | - |

| barley straw | 3,7 | 1,6 | 37,7 | 0,3 | 0,11 | 0,6 | 1,3 |

| oat straw | 4,1 | 2,2 | 36,1 | 0,2 | 0,1 | 0,7 | 1,3 |

| wheat straw | 3,9 | 1,5 | 36,9 | 0,2 | 0,1 | 0,6 | 0,8 |

| soy straw | 6,1 | 1,4 | 41,1 | 1,7 | 0,1 | 1,0 | 1,0 |

| clover hay | 11,7 | 3,4 | 29,2 | - | 0,2 | 1,9 | - |

| Corn cobs | 2,3 | 0,4 | 32,1 | - | 0,02 | 0,4 | 0,4 |

| sunflower husk | 19,6 | 1,1 | 35,9 | - | - | 3,1 | - |

| Cotton tows | 26,9 | 6,5 | 6,5 | 0,2 | 0,6 | 4,3 | 1,2 |

Quite often, when cultivating oyster mushrooms, cereal straw is used as the main component of the substrate. It is recommended to harvest straw in dry weather, immediately after harvesting, in an ecologically clean area, in an amount corresponding to the annual requirement of mushroom production.

If possible, it would be advisable to create a two-year supply of straw, since the amount of nitrogen in the straw after a year of storage almost doubles, in addition, it is better crushed, and its hygroscopicity increases (Table 3).

Table 3

Differences between freshly cut and last year's straw

When using sunflower husk, it is desirable to obtain it from one production. The husk should have a moisture content of no more than 15%, a fat content of no more than 3%, and kernels and dust particles - no more than 5%.

In order to calculate the content of dust particles, husks are taken from 5-10 places and mixed. From the resulting mass, three samples are taken and weighed, they are placed in turn in a sieve with 1 mm cells, filtering out dust particles. The remaining husk is weighed again. The percentage of dust particles is calculated by the formula P = P1 x 100% / P2, where P is the percentage of dust particles,%; L1 - the initial weight of the husk, g; L2 - the mass of the husk after sifting out dust particles, g.

To calculate the content of nuclei, the husk is taken from 5-10 places and mixed. From the resulting mass, three samples are taken and weighed. Husks and dust-like particles are screened out from the selected samples. The remaining core is weighed. Its percentage is determined by the formula: P \u003d R x 100% / L, where L is the weight of the husk, g; I is the mass of the nucleus, g; P is the percentage of the core,%.

It should be remembered that the quality of the husk is better at the beginning of the sunflower processing season.

Flax shive is quite widely used in mushroom production, although there is little data on its quality. Its humidity should not exceed 15%. It is desirable to store flax fire in the amount of annual need, although it is rather difficult to implement in practice, most enterprises using this species raw materials, work "from wheels".

Sawdust is the most difficult type of raw material in terms of procurement and standardization. It is practically impossible to obtain homogeneous material from sawmills, neither in terms of the ratio of fractions, nor in terms of tree species. It is undesirable to use coniferous wood (it needs a very long pretreatment). Due to the high humidity, fresh sawdust is almost impossible to store (Table 4).

Table 4

Humidity of wood of various species

Cotton noils, being record holders in terms of yield, are used infrequently due to the high price and low manufacturability. More often they act as a substrate component or additive. Cotton processing enterprises have whole line waste and intermediate products of processing, not all of which are suitable for cultivation of oyster mushrooms on them. Most often for these purposes use "nut standard No. 5". This raw material is well stored, since its moisture content usually does not exceed 10%.

It must be remembered that straw, sunflower husks, cotton tow, flax fire and sawdust are raw materials that are completely different in their biological nature. For each of the listed substrates, the rate of saturation with water, the ability to retain it for a long period of time, the optimal mode of heat treatment, the density of packing and, in the future, the yield per unit area vary within fairly wide limits. Within each type of plant material there are also varietal differences. A different thickness of the stem or a more pronounced wax coating can affect the preparation time of the raw material.

Nutritional Supplements. The main purpose of nutritional supplements is to optimize the amount of nitrogen in the substrate (Table 5). You need to know the nitrogen content in the nutrient supplement you are using, then by comparing the nitrogen content in the main components of the substrate and in the nutrient supplement, you can optimize its content in the substrate. Typically, nutrient additives make up from 1 to 10% of the dry weight of the substrate and have low selective properties. The introduction of a nutritional supplement is a separate technological method that must be clearly displayed in the technological production schedule.

Table 5

| Raw material | total nitrogen, % dry matter |

| Main Components | |

| aspen sawdust | 0,37 |

| Bonfire flax | 0,52 |

| wheat straw | 0,6 |

| Cotton tows | 0,62 |

| sunflower husk | 0,85 |

| Nutritional Supplements | |

| Hay (forbs) | 1,3 |

| sesame seed | 1,6 |

| clover hay | 2,0 |

| Malt sprouts | 2,03 |

| alfalfa hay | 2,4 |

| Kakavela | 2,46 |

| wheat bran | 2,58 |

| beer pellet | 4,42 |

| soy flour | 7,09 |

| feather flour | 12,0 |

Mineral Supplements. Mineral additives are used to improve the structure of the substrate, stabilize the pH, and alkalinize the medium.

To improve the structure, gypsum (alabaster) (CaSO 4) is used at an application rate of 1-10%.

To stabilize the pH, slaked lime (Ca (OH) 2) - 0.2-2%, chalk (CaCO 3) - 0.5-5% is used.

For alkalization, quicklime (CaO) is used, the consumption rate is 0.2-2%, slaked lime (Ca (OH) 2) - 0.2-2%, dolomite flour (CaC0 3 + MgCO 3) - 0.5- 5%, soda ash (Na 2 CO 3) - 0.1%, sodium hydroxide (NaOH) - 0.01%.

Water. According to modern requirements of sanitary and epidemiological supervision, only drinking water is allowed to be used in mushroom production. The use of lake and river water is prohibited.

Grinding. This first stage of preparation of the substrate allows you to make it more compact. Long straws are processed worse, between them, with insufficient compaction, voids are formed, which the mycelium must overcome. With a decrease in particle size, the specific surface of the substrate increases and the rate of assimilation of the substrate increases. Chopping is especially important when fresh, not yet compacted straw has to be used as a substrate. In industrial production, straw is crushed to a size of less than 5 cm using special machines (Fig. 1). At home, it will be enough to grind up to 5-10 cm.

Fig.1. Straw cutter

Mixing. For the preparation of complex substrates consisting of several components, mixing of the components will be required. Mixing will be effective only when the composition of each of the components is more or less homogeneous, in which case this process can be mechanized.

Moisturizing. This is a very important moment. The crushed substrate is soaked in water so that it absorbs the necessary supply of moisture for the entire cultivation period. For different substrate processing technologies, various ways moisture. In the xerothermic treatment of the substrate, wetting is carried out based on the moisture content of the incoming raw materials and the estimated amount of water or excess water over a certain period of time.

The technology, which involves pasteurization in a tunnel, involves moistening the straw in a pool or on a concrete platform for 1-2 days using wheeled equipment for crushing and loaders for tedding and loading into a pasteurization chamber. Hydrothermal treatment of the substrate combines moisture and heat treatment. Humidification is often supplemented by washing the substrate, which partially removes inhibitors of oyster mushroom mycelium growth, which under natural conditions can remain on straw for 3-4 months. Washing also removes some of the easily accessible sugars, and in the case of sunflower husks, small particles of kernels, the excess of which subsequently leads to sharp temperature fluctuations in the substrate. The introduction of lime during wetting or washing to some extent facilitates the saturation of the substrate with water. Excess moisture is removed either manually or with the help of special devices, for example, rollers are used for these purposes, similar to those installed on washing machines. Only they are larger and placed on a conveyor belt, through which the substrate is fed. At other enterprises, a jack adapted for this purpose is used to squeeze out excess moisture. Wet substrate is placed in plastic boxes and excess moisture is squeezed out.

The optimum moisture content of the substrate is 70%. It is defined as follows. The substrate selected from 5-10 places is mixed. Three samples are taken from the resulting mass, weighed and placed in an oven or microwave oven, drying to a constant weight. The moisture content of the raw material is calculated by the formula B = (M1 - M2) x 100% / M1, where B is the moisture content of the substrate; M1 is the mass of the sample taken, g; M2 is the mass of the dried sample, g.

When washing, substances easily soluble in water are washed out of the substrate. On the one hand, this somewhat reduces its digestibility for oyster mushrooms, but on the other hand, they are removed nutrients, which are much more important for microscopic fungi - oyster mushroom competitors. With an initial moisture content of the substrate of about 15%, 3-4 thousand liters of water per ton of substrate will be required to moisten it.

The mushroom is replete with useful trace elements and has a dense fleshy structure, therefore it does not lose its condition either in a pickled form during preservation or deep freezing. Along with these properties, oyster mushroom is environmentally friendly. food product, since it has unique property reject toxic substances. Growing oyster mushrooms in polycarbonate greenhouses does not require "intricate" care, although they have a number of important aspects. Some of the lovers of breeding oyster mushrooms in greenhouses not relevant to the question proper cooking mushroom substrate with due attention, therefore they are disappointed in this hobby, not receiving the proper return in the form of a rich harvest. Meanwhile, the quality of the substrate directly depends on how the process of oyster mushroom growth will take place.

How is the substrate for oyster mushrooms properly prepared? This process can be divided into three main steps:

- selection necessary components as a nutrient medium for future fungi;

- the process of preparing the substrate mixture;

- substrate incubation process.

Let's consider all three stages in detail.

Necessary components for the production of subtrates

A good basis for creating a substrate are the following components: straw of various crops, wood processing waste (wood chips, sawdust), corn stalks, grain husks. This organic is perfect. nutrient medium for propagation of mycelium (mushroom spores). It must be remembered that when selecting the necessary components for the substrate, it is better to make a choice in favor of, so to speak, " fresh product". If you neglect this rule, you can get a low-quality substrate, in which mold and other harmful microflora can develop, which ultimately will not allow you to get a high-quality mushroom crop.

The criterion for fresh chips and sawdust is the presence of a fresh woody smell. No presence of side toxic substances, such as varnishes, various chemical impregnations. The color of the wood can be from white to light yellow, which indicates its absolute freshness. The gray shade of sawdust indicates their old age, which means that they will soon rot. When preparing a woody base for the substrate, it is desirable to select hardwoods: linden, birch, poplar and similar species. Be sure to pay attention to the moisture content of sawdust and husks, which should not exceed allowable rate over 30 %. Otherwise, there is a high probability of mold formation in these components.

Substrate preparation

The use of several components at once will give the substrate better nutritional properties. The mixture is made up of the following proportions: sawdust or wood chips - 60%; straw - 30%; grain husk - 10%. Thus, a mixture rich in nitrogen will be obtained, which has a beneficial effect on the speed of obtaining the first harvest of oyster mushrooms.

All ingredients of the substrate mixture, except for bran, must be crushed. Straw and wood chips should have dimensions after their grinding within 2-4 cm. All components included in the substrate are thoroughly mixed and placed in a metal container.

The next step in the preparation of the substrate is its mandatory disinfection by the thermal method. To do this, water is added to a metal container with a ready-made dry mixture. Heat treatment is carried out by boiling the mixture in water at a temperature of 60-70 degrees within 3 hours. At the end of processing, the water is drained from the tank, and the mixture itself is laid out on a clean surface to cool it to a temperature of 20 degrees.

Naturally, you need to take care in advance of purchasing an oyster mushroom strain, as well as polypropylene bags measuring 95 by 56 cm, in which granulated sugar or flour. The substrate mixture is poured into clean bags, alternating it with mycelium.

The proportion of the contents of each bag should have 15 liters of mixture and 250-300 grams of mushroom strain. Entering the mycelium must be carried out exclusively with clean hands. Backfilling of the mixture must be done so that there are no voids in the bags. After the packing process, all bags are tightly tied at the neck with a rope. For professional mushroom growers, such ready-made bags are called substrate blocks.

Further, the bags with the substrate are placed in a special incubator, where the mycelium multiplies throughout the entire volume of each bag. The hatchery room should be disinfected with common household cleaners and painted with lime to prevent mold and microflora.

It is necessary to maintain the microclimate in the room within the established limits so that the process of mycelial growth proceeds at a constant and steady rate. To do this, you need to ensure the temperature in the incubator in the range of 20-24 degrees. If the temperature suddenly rises above 25 degrees, measures should be taken immediately to normalize temperature conditions. In addition to temperature, high humidity, equal to 90-95%, should also be maintained.

At the end of 12-14 days of stay in the substrate block incubator, there will be a certain sufficient amount of overgrown mycelium in each sealed bag. Thus, the substrate blocks are ready for the first harvest.

The material is provided by the magazine "SCHOOL OF MUSHROOMS"

Authors: TISHENKOV A.D., chief specialist of the "SCHOOL OF MUSHROOMS"

KARPOV F.F., Laboratory of Mushroom Growing, Russian State Medical University, Moscow

BRIEF DESCRIPTION OF TECHNOLOGY

Substrate composition

good foundation for the preparation of the substrate - high-quality wheat straw, which is harvested in dry time and stored dry in stacks or under a canopy (photo 1). You can store straw in heaps, folded from bales. The straw of winter wheat is considered the best, because. it is removed from the field during the drier season. You can use rye, barley, rice straw. Straw is brought into the right amount under a canopy or in a room and chopped with a straw cutter or roughage chopper to a size of 2–5 cm. Straw chopping is required for the convenience of dense packing of substrate blocks.

It is possible to use chips of deciduous trees as a basis (instead of straw). They also use substrates from flax fires, cotton linters, from sunflower husks, from a mixture of straw with sunflower husks. The substrate must be breathable even when wet. Straw cutting, wood chips, large sawdust from chain saws have the best air permeability. Ordinary sawdust from circular and band saws, hay, lawn grass do not provide sufficient air supply to the substrate, especially when waterlogged. Sawdust is good for small substrate blocks up to 3 kg in weight. To form larger blocks, it is better to use sawdust not as a base, but as an additive. Sawdust is a good addition to straw to increase its moisture capacity. Hay, especially hay legumes an excellent nutritional supplement. In any case, it is necessary to start mastering the technology with a substrate made of straw or hardwood chips without nutritional supplements. And additives should be used only after acquiring a certain cultivation experience. Especially dangerous is the use of bran, which, in high concentrations, worsens the aerobicity of the substrate and contributes to the development of molds.

heat treatment

The simplest and affordable way substrate preparation is a treatment in hot water.

For heat treatment, crushed wheat straw or the prepared mixture is packed in woven polypropylene bags (for example, from sugar, but without a polyethylene liner). The bags with the substrate are placed in a metal tank (photo 2). It is better to have an insulated (coated with thermal insulation) tank. Then the substrate is poured with hot water or the water is heated with an electric heater to 70–75°C and kept for 3–6 hours at 65–70°C. The temperature should be controlled throughout the volume of the tank. And in the lower layers, and in the upper, and in the middle of the substrate, and near the walls of the tank, the temperature should not be lower than 65°C and not higher than 75°C. If necessary, water is heated with an electric heater or boiling water is added to maintain the temperature. Then the water is drained through the valve at the bottom of the tank and the substrate is left for a day to slowly cool and free from free water. During this period, uncontrolled fermentation and accumulation of thermophiles in the substrate take place, which increases the selectivity of the substrate in relation to molds. To drain free water from the substrate, a grate or mesh must be installed above the bottom of the tank. It is possible to load the substrate without bags directly into the tank, but then the process of unloading the substrate with a pitchfork will be quite time-consuming. When draining water, air is sucked into the substrate from the room. A hermetically sealed tank should have a hole on top - a pipe with a filter (cotton) so that dirty outside air does not enter the substrate. However, the impact of this pollution is many times lower than infection in a clean zone at the time of inoculation, if the personnel are dressed in dirty clothes and shoes, or if a lot of dirty air from neighboring rooms enters the zone.

Operating schedule:

- th day. Loading raw materials into the tank. gulf hot water. Heat treatment. Draining.

- th day. Slow cooling from 65°C to 45°C. "Fermentation" of the substrate.

- th day. Unloading the substrate with a temperature of 40°C. Inoculation and packaging.

Inoculation

The cooled substrate, if necessary, is additionally squeezed out of excess water and transferred to the room for inoculation. The inoculation room, especially the surface of the tables, should be pre-washed with a 1% bleach solution. The surface of the tables after treatment with bleach must be washed clean water. During inoculation (seeding with mycelium of the substrate), the door and the airlock of the inoculation room must be closed.

At the moment of transfer of the substrate blocks from the inoculation room to the incubation chamber (if it is behind the wall), the fans in the incubation chamber are turned off. These precautions should prevent contamination of the substrate through the air with mold spores, which are always present in the straw and in the cultivation chambers.

To inoculate the substrate with oyster mushroom mycelium, the substrate is shaken out on a table with a metal coating and mixed with mycelium. It is very important that sowing is carried out with clean hands or clean rubber gloves. The mycelium of Russian manufacturers is added in the amount of 3-5% by weight of the finished substrate, imported mycelium - in the range of 1.6-2.5%.