A steep moonshine apparatus with your own hands. Moonshine apparatus at home with their own hands

Hello everyone! For a long time I promised to write this article, but he was constantly postponed. It's time to fulfill a promise. Today I will tell how to make a moonshine apparatus from the pressure cooker with your own hands.

What is the moonshine apparatus

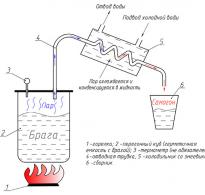

Let's first remind you to start, from which it consists and how the homemade moonshine apparatus works. The simplest construction includes a distillation cube (boiling capacity) and a refrigerator (direct or serpentine). The diagram is shown in the figure below.

We make a distillation cubic

I will make a distillation cube from the old Soviet aluminum pressure cooker for 6 liters. It is an almost perfect option for this.

I speak almost, because She has a significant drawback - its volume. You can pour into such a container not more than 5 liters of Braga, from which approximately 1 liter of 45% of the moonshine.

I do not lie to tell you, but it's enough to start driving a moonshine and understand whether you want to do this business. And the occupation is very exciting, believe me.

So, we have such a pressure cooker.

I got it from my parents, but also to buy it will not be difficult. I just found at Avito exactly the same as 400 rubles.

First of all, it is necessary to cut into the nipple cover to connect a distillation cube with a refrigerator. I will insert this, with a thread on ½ ".

In the lid there are already two holes for valves for pressure relief, we will not touch them. Let them perform their function. We will make a new hole with a drill on a tree with a size of 20.

Why on wood? Yes, it is just much cheaper than the metal drill, and the aluminum cuts very well.

First you need to mark the center and drill a small drill hole for centering.

And then drill it with a large drill.

If there are inaccurate edges, they must be cleaned with a small notch with a shallow notch. Now you can insert nipple.

After the drill size 20, the hole is well suited for nipple ½ ", I even had to apply the key to be screwed. He sat down so tightly that no additional gaskets or seals do not need.

From the inside, tighten the nipple nut.

It screws up the fitting for fastening the hose Ø12 mm.

If your pressure cooker has a gasket, the distillation cube for a homemade moonshine is ready. I did not have it. Therefore, we will make it.

We make a gasket for sealing cube

What a rubber got here is not suitable here, with contact with the moonshine couples, it will smell and spoil our entire product. It needs silicone here, and not simple, but food.

You can buy a ready-made gasket or if you do not find a suitable size, buy a sheet and cut the gasket yourself. They are sold in stores for moonshivers and in stores with laboratory equipment.

I will make a laying of liquid silicone for aquariums. It can be bought in pet stores, construction supermarkets and plumbing stores.

It is necessary for aquariums, it is precisely safe and does not give extraneous smells.

Fill with a small slide groove for laying on the lid and let Silicon dry. After a day, you can already start distillation.

Go to the next step.

We make a refrigerator

Than to connect details

Now it remains only to connect the distillation cube and refrigerator. For this, I use a silicone hose with an inner diameter of 12 mm. The hose should also be made of food silicone. No rubber or PVC!

Now the moonshine apparatus is ready. In order to prepare your first drink this is enough.

That's all. The process is very simple and not long. If you have ideas or comments, then leave them in the comments. I am always happy with constructive criticism. Also subscribe to the news, I will soon plan to add braga recipes.

So far. Dorofeev Paul.

The distiller in moonshine is needed to clean the fluid from harmful impurities. Each moonshner can make such a device with their own hands. Make a distiller is easy, but some tools will be required, objects and some time. But at the exit it will turn out a high-quality, purified product.

The moonshine apparatus is used for distillation of the liquid in order to obtain a strong alcoholic beverage. As a rule, it consists of such parts:

- Distilted cube. This is a reservoir where BRAG is poured and heated in it. For it, you can use any container that is tightly closed and is not afraid of high temperatures and pressure. Bidone, pressing, saucepan, perfectly suitable.

- Condenser. There are various tubes for gas condensation.

- Capacities for the finished product. Usually, the moonshoes use glass jars for the final liquid. But you can take other containers, the main thing is to be able to monitor the level.

Types of distillers

Distillers are different types:

- Industrial. In industry, special columns for rectification are used to work out clean alcohol.

- Household. The devices have a less complex design, but with a multi-stage distillation, a high-quality moonshine is obtained.

- Homemade structures. They are more economical, and with a properly built process, the product is not worse than the factory. At the same time, the moonshine knows which elements he used for him.

The principle of operation of distillers is the same. But the size, materials and the design itself have significant differences.

In addition, moonshine devices are:

- Flowing. Such designs are connected to the water supply.

- Unfinished. Filled with distilled liquid and do not require connection to the water supply.

Some distillers are equipped with sun-plane, deflements, thermometers, which allows you to clearly control the distillation process.

Distiller for moonshine do it yourself

There are a lot of diverse moonshine devices from the store, but if the moonshine makes the design itself, it knows exactly what details are used how strong they are and reliable.

The distiller do it yourself easy. To begin with, pick up the container for distillation. It should be completely hermetic. Many use large bidones for milk. They are equipped with a necessary lid, which is easily closed and opens. The throat at the bidon is wide, there are handles for carrying.

An enameled saucepan with a lid is suitable. It can withstand high temperature. The capacity is distinguished by litter, so you can drive out so much mogon, how many you want. In the cover of the dishes, make a hole through which steam will come.

Often, the moonshoes are used for a distilted cube with stainless steel pressure cooker. She has a comfortable cover, safety valves.

Capacity Choose based on the needs and capabilities. For a small amount of moonshine, sweaters are suitable or dishes with a small litter. In order to drive a lot of moonshine, use a bidon or a large container pot.

Kuba is attached to the serpent. Copper tubes are suitable, they have good thermal conductivity and are less oxidized. Glass tubes are fragile, it is hard to make it. You can apply an aluminum tube, but it is oxidized with time.

Prepare a container for the finished product. It is more convenient to use glass jars, they can be seen how clean the product is obtained, and you can observe the level.

After the necessary parts are prepared, proceed to the distillator assembly:

- Remove the elastic band from the cube. For safety, the lid is attached by the reinforced tape, sealant of silicone, or the dough (flour and water). Check that everything dries and firmly kept.

- In the distillation capacitance cover, make a hole and insert the adapter there. For this purpose, a plumbing tube of suitable diameter, a copper tube or a wooden cylinder is suitable. Screw capacitor on it.

- To connect the coil with water, we use rubber or. Check the tightness! With the help of the hose, water is supplied, steam is given and the finished product is displayed. Silicone hoses are better, resistant to high temperatures, fungus, durable, elastic.

Our distiller is ready, you can proceed to moonshine.

Unconventional distillers for moonshine

Some moonshoes use unconventional parts for the moonshine. Distillers are made from aquarium, old samovars, metal pipes. Refrigerator capacitors use to cool the coil. But it is necessary to remember the sealing, thermal conductivity, high pressure and temperature.

The distiller is not difficult and cheap to do. In this case, experienced moonshoes will monitor its reliability, strength and adjust the quality of the product.

As it turned out, the Department of Moonshit is very popular among subscribers. And if earlier the topics touched, mostly separate parts, today we will tell how to make the simplest moonshine apparatus with their own hands.

To begin with, it is necessary to determine that the moonshine is the preparation of alcohol by distillation of Braga at home. Alcohol is always obtained by the same technology, regardless of the scale - for homemade or industrial production. Starchy or sahamo-containing raw materials are manufactured, where water and yeast are added. In the process of fermentation, the so-called develops. Artificial world where single-cell mushrooms live. The result of their vital activity is ethyl, methyl, propyl and other alcohols with the addition of aldehydes and acetone.

Since all products, except for ethyl alcohol, are harmful to human, the task of moonshine is to get pure ethyl alcohol in the non-mean concentration. For these purposes, rectification is carried out, that is, the separation of the product into several fractions. You can buy or, but much easier and faster to make the easiest motherwise apparatus.

The simplest moonshine apparatus

In order to make such a design, only 2 larger and smaller diameters will be needed (in Fig. 2 and 4) and the pan (in Fig. 3).

This design works as follows. In the pan poured BRAG. From above on the struts put a plate of a smaller diameter so that it does not plunge into a boiling braga. A plate of larger diameter is installed on the saucepan, where cold water is poured.

In the boiling process, alcohol pairs are allocated and settled on a small plate. As a result, you get the minimum quantity of moonshine (from 1 liter of braga no more than 80 ml) with a large concentration of fusion oils. Honestly, such a moonshine is not what the inside take, but even externally use dangerous. This method was very popular in the Soviet Union at the time of the "dry" law. It is clear that the number of poisoning with such surrogate approached the absolute majority, from where, in fact, the belief that the moonshine was pure poison.

In this case, no moonshine is dangerous, but the concentration of hazardous substances - fusion oils, acetone and aldehydes. Only double and even triple distillation can give at the exit clean and safe for life and health product.

We led this information only to describe previously existing ways. We do not recommend such a device at home - we will not be able to drink, and the smell in the apartment will delay at least a week.

How to make a simple moonshine apparatus

In this case, the design includes a distillation cube and refrigerator. This is also a simple option, but allowing you to get a high-quality drink.

Always distillation distillate at least 2 times and use a surfactant. So you get rid of harmful fuses as much as possible. After cleaning with coal.

Distillation

For this, any enameled or stainless steel container closing tightly cover is suitable. The latter should be closed so tight so that it does not have an overpressure from the inside.

The second prerequisite is the presence of an outlet, through which it will not be divided into steam fractions. To this end, in the lid make through hole and screw the fitting.

The third condition - tightness - smoothly follows from the first. If you provide a reliable fastening of the covers in Cuba, the tightness will be provided. Someone makes a dough cover, others use silicone gaskets. We recommend using pressure cookers. The price of the simplest model is 1500-2000 rubles. If you are planning to cook the moonshine, it makes sense to buy it.

However, the pressure cooker has one serious drawback - its volume. The maximum, which we met on sale, is designed for 6 liters, it became possible to get a 4.5 liter to the brags (no more than 2/3 of the volume). This is at the exit of a little less liter of the mogon. It will be not enough for home use.

If this volume does not suit, buy a special distillation cube with a capacity of 10 liters. The average price is 3200-4000 rubles.

A daily bidon with a twisting tight cap will be affordable and suitable in size. It really will be necessary to deceive the test after the wallet is token, but this is even plus - in the house it will smell not a sivery, but fresh pastries.

How to make a distillation cube in just half an hour - video

Refrigerator

The refrigerator in the moonshine apparatus is divided into 2 main species depending on the water supply method:

- filler (accumulative);

- flowing.

The first option is very very bad in terms of the production of moonshine. This refrigerator can only be used if there are big problems in the house with water. The principle of operation of such a refrigerator is based on the bay of immediate cold water and replacing it in the process of moonshine.

What is bad such a refrigerator? The fact that the water is still heated, even if you change it quite often. The warmer water, the slower there is a division into fractions, the smaller, respectively, you will receive a finished product.

The flowing refrigerator is connected to the water supply and all the time while the cooking is coming, water passes through it, physically not so much to heat the critical limit.

.jpg)

The filling refrigerator can only be used when there is no actual ability to connect the plumbing.

Coil

A mandatory element of any refrigerator is a serpentine, a glass, copper or stainless steel spiral tube, according to which alcohol-containing pairs move from distillation where to an acceptance capacity, and simply divided into a vapor and liquid fraction.

Some moonshoes prefer to use laboratory coils made of glass. Immediately say, our cuisine is far from a laboratory and people here goes not prepared for such almost sterile conditions. And glass things have the property to be broken. It is best to use a copper coil, characterized by a great degree of heat transfer, safe in operation and standing literally a penny.

.jpg)

The refrigerator with a copper coil includes the following required elements:

- water capacity;

- sounding with 2 fittings - the entrance of the vapor and the output of the moonshine;

- 2 fittings for inlet / out of flow water for cooling.

In the photo examples of the simplest and therefore effective refrigerators.

On the video you can see how to make the simplest refrigerator based on corrugations - gas flexible tube. Only 1 hour and you can run to work.

Final assembly

Actually, on this, the manufacture of the moonshine is almost over. It remains only to collect together all components.

For the connection you need to use only (!!!) silicone hoses. It is forbidden when distilcing alcohol use PVC hoses, it is very and very dangerous.

.jpg)

In order to distinguish the Silicone Hose from PVC, you can set fire to it. With burning there will be no smell. At the same time, the hose hose is pleasant to the touch.

Outdoor

Whoever spoke about the need for the need or impossibility of this detail, we insist on the fact that the product should be as clean as possible. Not as alcohol-rectifies, it is really practically poison, but so that the events of the last evening will clearly remember the morning.

Arykharnik is used to separate the seawous oils from the alcohol-containing steam and eliminating braga residues to the finished product.

You can buy an already ready-made an armor, which will cost 1800-2200 rubles or make it from the usual bank.

You take the bank - 1- or 2 liter with a twisting lid. In the lid make holes under two fittings input and output.

.jpg)

Connect two hose to the fitters - one goes from a distilted cube, the other - it goes into the refrigerator.

It is best to make a stainless steel surgear and provide drainage of sigh oil. When distilcing a large number of Braga, the latter begin to move, negatively affecting the taste of the final product.

Now the most simple moonshine machine is ready!

For those who else have any questions - video instructions from experienced moonshoes

(The device will be described in the article) is represented by a wide range of models. First of all, the famous brands that possess an attractive design and are made of high-quality materials. In addition, similar aggregates are equipped with electric heating, and their cost is high enough. The basis of such devices are stainless steel or copper. When connecting parts, it is resorted to argon welding.

Varieties of moonshine vehicles

The moonshine apparatus, the device of which depends on the characteristics of a particular model, may have many structures. Recently, their row replenished with miniature alcohols. The main distinguishing feature of such devices is the uniformity of use. It is enough to connect an aggregate to electric and water and filling it with a braga. Temperature control and other parameters are not needed. The device turns off automatically when the alcoholic beverage is ready.

Portuguese alambics are very popular. They are made of copper. The distillation cube has a round shape. The adapter looks like a swan neck. This configuration provides condensate output in its pure form. Due to this, the level of alcohol concentration rises at times. Alambics are used in the production of vintage wines.

Wide distribution received universal designs that are collected in 19 minutes. Such a device is used for rectification and distillation.

What is the apparatus for moonshit?

The moonshine apparatus, the device and characteristics can have inconsistent indicators depending on the model and brand of the manufacturer, in any embodiment, includes the basic components:

According to the principle of the moonshine apparatus

The device functions by different schemes, depending on which model is meant. For example, take a classic design with a coil.

In this configuration of Braga, containing alcohol, is brought to a boil in hermetic capacity, to which the coil is connected. Bidones, tank, flask from 25 to 38 liters appear in self-made devices in the role of the tank. Often used and pan. When boiling, the pair of braga is derived in the serpent, where the liquid is cooled due to the constant circulation in the outer part of the cold water coil. Condensate flows into a cooked container in the form of a moonshine.

At the beginning of the boiling of the braga, light-boiling components evaporate, and the content of the head-air components increases. The alcohol is extracted from the brody not fully, which worsens the quality of the moonshine.

In order to avoid this negative factor in the design of the moonshine, an armhire is included or a reflux. The device of the moonshine with a surfactant, the drawings of which are presented in the article, involves the elimination of the head-air components by condensation.

The deflectman is located between the cube and the coil. It is represented by a capacity of 3 liters. It occurs in the process of condensation of the heading components.

Moonshine without a serpentine

Basically, all types of moonshine apparatuses and their device assume the presence of a coil. But there are also schemes where you can do without this component. The priority of this design is the simplicity of manufacturing, but not use. Such moonshine devices are homemade and do not always give high product quality.

Their foundation is a large saucepan - 50 liters and more. Braga is poured into it. In Braga, the tank is lowered for collecting moonshine. It floats on the surface of the fluid, sometimes tested above the surface of the braga on a special stand.

Scheme of the moonshine unit with a surfactant

Arykharnik is not a mandatory component of the device. The reflegemaker acts as cleaning the future alcohol from thus increasing its quality. Device of the moonshine with an ammunition, whose drawings are presented above, it is based on the fact that the boiling point of harmful components is higher than that of ethyl alcohol. In the deflegemator, harmful oils are condensed and stop evaporated, since heat energy is spent on evaporation of light components.

Pluses of a surfactant

Arykharnik purifies moonshine much more efficiently than chemicals (manganese, soda, activated carbon). Installation of an alley is light. It can be connected with any cube for distillation. He acts as a secondary distillation.

What is needed for the manufacture of a homemade surchant?

You will need:

- glass jar in 2 or 3 liters with a dense metal lid;

- two fittings with thread from the outside;

- two nuts;

- pencil;

- glue with high levels of thermal stability;

- awl.

Instructions for manufacture

The device involves the following actions:

In order for the braga not to get into the moonshine, they advise you to place the entering tube 20 mm below the output. This additional precautionary measure will be very useful for beginners in the event of moonsh. To improve the efficiency of the functioning of the reflux, it should be insulated. For example, from felt do something like a glass for a can or resort to the use of another insulant material.

In the models of the factory production, a moonshine unit with an ammuntela is made of stainless steel. The device of the moonshine apparatus is pretty problematic for such a design.

If you do not want to spend time on the manufacture of this detail, you can purchase a ready-made moonshine device. In the modern market there is a wide selection of aggregates of different volumes and technical parameters.

Moonshine apparatus "Germany"

High German quality on a very affordable price - this is what characterizes this device. Against the background of other aggregates, it has a high level of productivity and a range of innovative decisions in the design. The Moonshine Device "Germany", the device and characteristics of which allow you to produce high-quality alcoholic beverages with minimal costs of products, in the domestic market has been widely recognized. For example, from 2-3 kg of sugar sand the unit produces 3 liters of pure drink.

Construction of aggregate

The device features high quality welding and no seams.

The moonshine apparatus "Germany", the device and characteristics of which suggest that it is thought out to the smallest details, has the following indicators:

- wide tubes for the connection exclude the risk of blockage;

- determines the booster time of the moonshine and the end of the distillation;

- a wide neck makes it possible to thoroughly washing the aggregate from the inside;

- the steel thickness of 2 mm eliminates the burning beverage.

The device is made of high-quality stainless steel. It is made according to Standard 1.4301, adopted in Europe. This means that the drink will differ in purity.

All connections contain gaskets, thanks to which the distiller is absolutely sealed during moonshine. You will not feel at home the unpleasant smell of alcohol.

The arcuate tube ensures the flow of phlegm back to the cube. Thus, the concentration of alcohol at the output will be higher than that of the aggregates with the exit tube in the form of an angle.

Crane for cleansing

The unit "Germany" is equipped with a crane for draining bards. The thick, which remains after distillation of the wort, is poured. The faucet provides a slight pouring of the bards. Splitting the upper cover of the device will not need. This allows you to not interrupt the refinement process. This feature of the design is beneficial to the unit in a number of other devices presented in the market.

Wide neck

Ergonomic tank in the form of a cone and a fairly wide neck allow you to make the process of injection of braga, as well as flushing after distillation simple and convenient. Removable silicone gasket, which is located on the neck, gives high tightness to the device. In this case, extraneous odors are eliminated.

Convenience of the Sukh Starnik

Optimized design of the deflements, the presence of a removable cover for the preparation of exotic beverages, a specially thought out crane for draining the fusion oils allow you to make absolutely safe drink for health.

Equipment of the device

The "Germany" aggregate consists of:

- twelve tank;

- an armhire;

- refrigerator;

- thermometer;

- food hoses.

The buyer receives a book of recipes to him.

Moonshine apparatus "Japan"

Aggregate "Japan" ("Varisam") - a miracle of technology produced in Taiwan.

In the domestic market, this model appeared in 2015. Its cost is quite high.

The moonshine apparatus "Japan", the device and characteristics of which indicate that it sufficiently pays for funds spent on it, from the point of view of moonshoes differs with unusualness, both in design and configuration.

Equipment of the device

The volume of the distilted cube of the device is 28 liters. This is a standard indicator. There are no other configuration options. The unit is placed in a small box, unpacked which, you will see many different details. The device falls into your hands in a completely disassembled form. It will not be much difficult to assemble. This will help the attached instruction.

In addition to hoses for distillation, cranes and books of recipes, the hydraulic was also included. It serves to convert the device device for tincture of Braga. There is also a set of measuring dishes, which will delight accuracy lovers when cooking moonshine.

Design features of the device

The moonshine apparatus "Japan" is made of high quality. The seams are characterized by ideality. Such devices in our country are not produced.

The device has an unusual healer and a refrigerator. The peculiarity of the reflux is that he, according to engineers, separates all malicious components and does not allow them to get into the finished product. Thanks to this component, ethyl, methyl and water can be perfectly cleaned. Ceramics fillers, wood chips and aromatic additives are used as a filter.

Innovative solutions are also applied when creating a refrigerator - the main component of the moonshine unit. It has a dual configuration. Combined cooling consists of two heat exchangers - coil and leather-bearing. Indeed, the ideal solution that contributes to an increase in distillation performance up to 3 liters per hour.

Let's sum up

The aggregates "Germany" and "Japan" deserve the highest assessment. Moonshine, the device, design and level of productivity of which are very good, are designed to use both experienced moonshoes and beginners.

Although there are many home distillers in different price categories on the market, experienced dumbers prefer to make equipment independently or make an order to proven masters according to their own drawings and diagrams.

The advantage of this approach is not only in saving funds. Often made by your own hands the moonshine apparatus is more reliable and practical than the majority of store models with incomprehensible elements that contradict the laws of physics established only in order to attract the buyer and raise the price. Next, we consider the classic design of the moonshine (distillator), which is not equal in ease and efficiency.

Scheme of the moonshine with a surfactant

Scheme of the moonshine with a surfactant Connecting elements

Intermediate links play an important role. With incorrect selection of tubes or sealant, moonshine is muddy, with an anti-flavor, bad smelling and even dangerous to health. Therefore, the consideration of the design will begin with the connecting elements.

It is not worthwhile to "tightly" to weld all the tubes among themselves, it simplifies the assembly-disassembly of the device, but when cleaning causes a lot of problems.

Metal tubes made of stainless steel, aluminum or copper, as well as inert food or medical silicone hoses are most often used as a transport system. In terms of savings, safety, ease of care and operation, the best option is the tubes of food stainless steel.

It is important to be able to distinguish silicone hoses from the PVC made from PVC (polyvinyl chloride in contact with hot steam saturates alcohol with poisoning substances). PVC is burning with plenty of smoke and unpleasant odor. Silicone does not have a borony when burning, leaves barely caught smell and light ash. To the touch, silicone tubes are much softer than from PVC, and the price of them is about twice as high.

Left - Silicone, right - PVC

Left - Silicone, right - PVC To branch turns, the transition from one diameter to another and connecting different parts in metal pipelines, fittings and fittings are used, which can be found in plumbing stores or in building markets. Fittings made of brass, bronze and stainless steel (optimal option) for heat networks capable of withstanding high temperature and pressure are suitable for the manufacture of the moonshine apparatus. For sealing purposes, the use of heat-resistant glue and cold welding is allowed, the main thing is to avoid rubber gaskets.

Also, a organic substance can be used to seal the tubes - the usual dough that does not affect the distillate. The disadvantages are two: a long time goes to knead and close the joints, and after distillation, the dough you have to score.

Sealing test - touching ancient traditions with subsequent scraper 🙂

Sealing test - touching ancient traditions with subsequent scraper 🙂 The assembled moonshine apparatus should be sealed. If steam is seeping through the tubes, it is better to stop distillation, make the equipment to cool, repair the breakdown and only after that continue distillation. The depressurization is not only dangerous to the occurrence of a fire, but also leads to a significant loss of moonshine (10-70%).

Distillation

It is a container in which Braga boils in the heating process. Parameters:

1. Material. Aluminum - most often met in the "Soviet" moonshine devices due to the widespread spread of dairy aluminum bids. Aluminum partially enters into a reaction with acids and alcohol in Braga, so at a frequent operation of aluminum distillation (especially old) after half a year come into disrepair - there appears to flow.

Enameled dishes - neutral to acids and alcohols. With proper use (without blows and scratches, enamel) can serve 3-5 years even with regular use.

Food stainless steel is the best and reliable option, but stainless steel cubes are expensive, often under their kind sell ordinary steel with galvanized or nickel-plated coating, which is not so durable.

Copper Cubes are suitable, though, in most cases, this is an unjustifiably expenly solution, especially for novice moonshoes.

2. Volume and dimensions. The volume of the distillation cube depends on the needs of the moonshine, the optimal option for home use is 25-35 liters.

Attention! For security purposes, the distillation cube can be filled with Maximum 80% of the volume, consider this when choosing a container. It is also very important that the lid is removable, and the width of the neck is quite large for comfortable cleaning of the container after distillation.

The volume of the cube is calculated based on the need for the finished product. For example, in a capacity of 30 liters per distillation, it is possible to obtain up to 2.88 liters of pure alcohol (or 7.2 liters of the moonshine fortress of 40%). Maximum loading of Braga - 24 liters (30 * 0.8 \u003d 24). The middle fortress is correctly made by Braga - 12%. The amount of distillate at the output - 24 * 0.12 \u003d 2.88 (in recalculation to absolute alcohol fortress 100%). In practice there will always be a loss of mogon 8-15%.

Do not forget about the dimensions. The distillation cube is at least to be placed on the stove or another heating element, to be stable and not close the approach to the entire device. This is the basis for safety safety.

3. Choosing a suitable container. It is often used in homemade moonshit devices, the containers are used, which were originally intended for other needs: dairy beedons, pressure coarse or spacious enameled pans.

The cube should be reliable - expand when heated, withstand high temperature and pressure (180-220 Pa). Homemade welded tanks are very dangerous, since there is a risk that the welding seam will burst at the most inopportune moment.

A significant lack of cubes from the pressure cooker is a small volume, but these containers are originally sealed. A single refinement is required - drill a hole in the lid under the tube to exit steam. Described in a separate article.

In the pressure cooker at a time a lot of braga do not overtake - too small cube

In the pressure cooker at a time a lot of braga do not overtake - too small cube Enameled pots are convenient because the play-playing is not to overflow, but immediately put on distillation as it is (it is incorrect because the heated precipitate increases the amount of harmful impurities in the moonshine, worsens the aroma and taste). Minus Pots - It is difficult to seal the lid.

Milk bidon, made of aluminum or stainless steel, is the most practical solution. The only one requiring compulsory elimination, the lack of bidones is a rubber gasket on the lid. The fact is that alcohol pairs absorb substances from rubber, it negatively affects quality, taste and smell of moonshine. Rubber gaskets need to be replaced with silicone (from aquarium silicone).

Bidon with built-in Tanns - cheap and practical. From above two holes for steam and thermometer

Bidon with built-in Tanns - cheap and practical. From above two holes for steam and thermometer How to make a distillation cube of the moonshine from the bidon

It is not enough to determine the amount of capacity, you need to prepare a cube to use - drill a steam hole, seal the lid and connections. Next, we will look at the improvement of the container on the example of an old milk bidon, but this method of sealing the lid is suitable in other cases.

Bidone refinement technology:

1. Remove the rubber gasket from the lid.

2. Apply an aquarium silicone sealant on the metal edges and leave until complete drying. Repeat the procedure for another 2-3 times.

3. On the bidon neck, impose cellophane and close the lid. Leave a couple of hours to complete drying. It turns out a silicone seal that replaces the rubber gasket.

Received result

Received result An alternative, simpler sealing method is to wind up the tires with several layers of fum-tape and reveal 60 minutes in boiling water.

4. Make a hole in the lid hole for connecting with a coil or an amar furnace. If the inner diameter of the serpentine is 12 mm, the suitable hole for the pipe in the bidon is 22 mm and the thread is 0.5 inches. Adapters are sold in plumbing equipment stores.

To extend the life of Wash the Bidone after each distillation with soap with a large number of running water. Use soda and other cleaning products is strictly prohibited.

Fridge of the moonshine

It consists of two parts - the coil (twisted tube) and the tank for cooling this tube. The cooling compartment is the most important element of the whole structure, the functioning of which the number and quality of the moonshine depends on the functioning.

Settings Zmeevika

1. Material. It should not be reacted with alcohol (or minimally contact), be safe and not toxic, to withstand high temperature (up to 100 ° C), have a high thermal conductivity. Based on the requirements, four options are possible: copper, aluminum, stainless steel (grades for food) and glass.

The highest thermal conductivity in copper, one more advantage - comparative ease of processing (soldering). But this material has one feature - a copper coil requires periodic cleaning with vinegar or citric acid with boiling water (preferably after each distillation), otherwise the flare accumulated after oxidation, the flare will negatively affect the quality of the moonshine.

All complained moonshoes are poorly cleaning their devices. In the global practice of distillation, copper is considered the best or even solved material (France, Scotland) for the manufacture of distillers (alambics). Easy oxidation of copper with alcohol contributes to improving taste, because reduces the amount of impurities with a bad smell, and the concentration of substances making moonshine softly increases.

The second thermal conductivity material for the coil is aluminum (worse than copper 1.6 times). The advantages of aluminum are affordable, low cost and simplicity of processing. But there is a disadvantage - minimal oxidation, which, unlike copper, does not secrete useful substances into the moonshine, so aluminum coils are not very common.

By thermal conductivity, food stainless steel is inferior to copper 3-4 times. But this material does not react with alcohol and does not oxidize. Another drawback along with low thermal conductivity is a comparative complexity of processing.

Make a glass coil at home is not possible, without special equipment it is easier to buy a ready laboratory device. The glass is inert with respect to alcohol, but very fragile and has low thermal conductivity.

Copper coil - the best, but requires regular cleaning

Copper coil - the best, but requires regular cleaning 2. Dimensions and thickness of the tube. The longer the tube, the greater the contact area of \u200b\u200bsteam with a cooling element. But there is a side effect of a large length - the hydraulic resistance increases (the condensed pairs move along the tube already in the liquid state), which reduces the driving speed.

The optimal length of the snake tube (before the bend) is 1.5-2 meters.

The larger the inner diameter of the serpentine (section), the lower the hydraulic resistance and more efficiently cooling (due to the increase in the area of \u200b\u200bcontact with the walls). But the tubes of a very large diameter of cumbersome, require a lot of water for cooling and complex in processing, so you have to look for a "golden middle".

The minimum wall thickness increases the thermal conductivity, which improves the condensation of alcohol vapors. But too thin tubes are very fragile and with intensive exploitation of the moonshine, they break quickly.

Suitable coil thickness - 0.9-1.1 mm.

3. Orientation in space. Three connectivity options are possible: horizontal, vertical and inclined.

Upcable conditions, the vertical location of the coil is the most correct, since the condensed moonshine flows into the receiving container by gravity, without creating obstacles to the movement of alcohol vapors. The vertical coil of steam can be served on top or bottom. To minimize resistance, correct steam to the upper part.

Refrigerator Reservoir Parameters

1. Substance. At home, the serpent cooled by air, water or ice. In the overwhelming majority of designs, water cooling is used as the simplest and more efficient.

Air cooling - beautiful view, but low efficiency

Air cooling - beautiful view, but low efficiency 2. Heat removal scheme. Systems are open (working on running water) and closed (water remains in the tank, not circulating, for example, a serpentine is lowered in a bucket). In terms of implementing and saving, closed systems are easier and more profitable, but worse cooler cooler, which increases the loss of moonshine and badly affects quality.

Bucket - classic example of a closed water cooling circuit

Bucket - classic example of a closed water cooling circuit Flowing schemes are more complicated in the manufacture, more water or energy for pumping (providing circulation of a stable water volume for savings) are used, but they require a smaller reservoir and will issue high quality distillates from other things being equal.

From the correctly made refrigerator (snake plus a water circulation system) moonshine comes out with a cold or room temperature, but not warm or hot. It is important to choose the optimal heating intensity (not exceeding the maximum allowable heat supply power) so that the entire system is effectively coping with steam condensation.

3. The direction of water supply. Correctly serve water in the refrigerator from below, but to output from above, so that the water moves to meet a pair, creating an opposite, otherwise the bottom of the coil will be badly cooled.

Production of the refrigerator (cooler)

It will take copper, aluminum or stainless steel tube with a length of 1.5-2 meters, with a diameter of 8-12 mm and a wall thickness of 0.9-1.1 mm. As a tank for installing a coil, a plastic or metal pipe with a diameter of 75-80 mm is suitable. The drawing of the refrigerator of the moonshine is shown in the photo.

Sequencing:

1. Change tube to fill sand, soda, or other dry, bulk material so that the metal is not flattened when curling. If there is no dry materials under hand, the tube can be simply filled with water and freeze.

2. Ends to score with wooden pegs (choppers) so that the sand does not fall down. You can tightly clamp or pour. One of the ends is preferably to fight the nut.

3. Hound up the tube on any smooth, cylindrical object with a smooth section of a suitable diameter (according to the drawing - 35 mm). The step between the turns is 12 mm.

The number of turns in the coil has no fundamental importance, with the values \u200b\u200bof the length, diameter and thickness indicated in the article, correctly take a step between the turns of 12 mm.

4. Release the ends of the finished coil. Pour sand, rinse with water under pressure.

5. On the cooler body, install nozzles for feeding and removing water.

6. Place a serpentine inside the housing. Top and bottom to install plugs. Sealing all connections.

Ready cooler in the assembly

Ready cooler in the assembly The speed of the cooler of this design is up to 3 liters of the moonshine per hour.

Harmonic and bubbler

Optional, but desirable (especially for beginners) modules of the moonshine.

Arykharnik - a hermetic glass or metal capacity between the distillation cube and the refrigerator, falling into which the pairs are first cooled, and then some of the substances boils back and moves to the serpent.

The principle of the operation of the drill. Due to the sharp decline in pressure (the volumes of the supply tube and banks differ hundreds of times) the temperature drops, as a result of steam passes into the liquid phase (condensed), but immediately heats up the new portion of the hot pair from the cube, turning into a gaseous state again. But part of the water and the sigh oil with high boiling point do not have time to boil over this short moment of changing the aggregate state and remain at the bottom of the tank.

Barboter in the moonshine - A device intended for transmitting alcohol vapors through a layer of liquid (water). It is constructively different from the surfactant only the presence of water in the tank before the start of distillation (not always), and in the fact that the steam tube is lowered to the can almost to the bottom. The appointment and principle of the bubbler's operation are the same as the surfactant.

CONNECTED ONERGARNIK

CONNECTED ONERGARNIK

Barbotter - feeding pairs of tube is lowered closer to the bottom, distillate flavored lemon zest

Barbotter - feeding pairs of tube is lowered closer to the bottom, distillate flavored lemon zest Advantages of an amar furnace (Barbotter):

- is protection against splashes - brotherhoods in a ready-made moonshine with too strong heating;

- makes distillate stronger;

- cleans the moonshine from some vest oils (only a small part);

- allows aromatize alcohol during distillation (enough to put in the jar of zitrus fruits, pieces of apple, etc.).

It is advisable to use one hand or bubbler in the moonshine apparatus. Sequential installation 2-6 pieces only leads to an increase in the moonshine fortress, but does not affect cleaning.

If the moonshine is strong at the outlet, for example, even 80-90 degrees, then it does not mean that the drink is well cleaned, just water remained in the drill and (or) the bbusers remained to be condensed in the coil, reducing the distillate fortress. All harmful impurities that can be cleaned by an amar furnace stay in the first bank, and only water is removed from the moonshine. It is not necessary to think that according to the degree of purification of 6-8, driparters can rectify or fractional distillation, it is physically impossible.

How to make an armor or bubbler

The volume of the dry-air capacity (bubbler) must be 10 times less than the volume of the distillation cube.

You will need:

- glass jar with a metal cover or other hermetic container;

- 2 fittings;

- 2 nuts;

- marker;

- awl;

- hem-resistant glue or cold welding.

Instruction:

1. Mark the diameter of the holes in the places of the intended connection: attach the fitting to the lid and circling the marker.

2. Make holes. The easiest option is to take shill along the drawn lines until the cover of the cover won't go through.

3. Install the fitting and secure nuts. For sealing, handle holes with the outer and inside with cold welding or heat-resistant glue.

Inner side

Inner side

Outer side

Outer side

Barbotera manufacturer sequence

Barbotera manufacturer sequence 4. When connected to the moonshine apparatus, it should be borne in mind that in the surfactant the introductory tube must be lower than 15-30 mm (deeper by the bank). In the bubbler, the incoming tube passes throughout the height of the can, without touching the bottom at a distance of 2-3 cm.

With the wrong bubbler connection (steam is fed through a short end, and trying to exit a long) pressure in the bank significantly increases and an explosion may happen!

The lack of bubblers and drums from the can only one - there is no drain for the accumulated liquid (it is necessary to unscrew), and during fractional distillation it is desirable to clean the tank before the selection of the "body" (the main fraction).

More sophisticated surgery with drain

More sophisticated surgery with drain Methods of heating of the moonshine

1. Open fire. In most cases, it means heating on a gas stove or burner, but there are also coal and firewood. The advantages of this method: simplicity, availability and often economy.

Disadvantages:

- high inertia - quickly reduce or increase power will not work, as a result control the temperature in Cuba is difficult, experience is required;

- heat the distillation cube to reduce heat loss in order to save it is very difficult;

- installing automation is almost useless;

- high fire hazard open fire.

Fresh air distillation firewood. What device, such and the color of the moonshine

Fresh air distillation firewood. What device, such and the color of the moonshine 2. Built-in electric tagnes. Devices (one or several somewhat) mounted directly to the cube. Suitable stainless steel or brass lathes.

Benefits:

- fast temperature change (high handling);

- ability to build automation and insulate the cube.

Disadvantages:

- solid particles can be burned to the working surface of the TENOV, careful filtering of the braga before distillation is required;

- often heated on electricity is more expensive than gas;

- from time to time heating elements burn out.

3. Induction stove. It works at the expense of electricity, it is stationary and portable (in moonshine is used more often).

Benefits:

- low inertia is a quick change in the heating intensity;

- good temperature control - induction plates are equipped with automation, you do not need to install separate blocks;

- in comparison with Tenans, the entire surface of the bottom of the Cuba is evenly heated, the burning of braga happens in rare cases.

Disadvantages:

- the cost of induction plates is quite high;

- you can use only distillation cubes from materials containing a magnet (stainless steel, cast iron), in turn aluminum and copper containers without welded to the bottom of the magnetoscale inserts for heating are not suitable.

On the induction plate you can heat only stainless steel and cast iron cubes

On the induction plate you can heat only stainless steel and cast iron cubes 4. Heating with steam (steam generator). First, the water is adjusted to a boil and served directly into the container or on the outer walls. The system allows you to control (automate) the whole process and exclude the risk of burning, so suitable for distillation of thick brah. But in mind the complexity of the implementation of the design and the need to purchase (manufacturing) of special equipment (steam generator) will not be further considered here.

Installing thermometers in the moonshine

Without measurement of temperature, you can do, but the correctly installed thermometer allows you to change the container during fractional distillation on time and adjust the heating intensity.

The moonshops use three types of thermometers (according to the principle of operation):

- bimetallic - as a sensor is a tape or a metal spiral;

- electronic - a special conductor changes resistance when fluctuating the temperature;

- digital - measurements are recorded due to pressure change.

Bimetallic thermometers are the most reliable, but the accuracy of these devices leaves much to be desired. Electronic degrees are much more accurate, but at the slightest impact they can break or show an irregular temperature. Digital thermometers - leaders in accuracy, but are expensive.

During distillation, it is impossible to fully rely on the thermometer readings, especially the first times, when the working modes of the homemade moonshine can not be tested. Temperature values \u200b\u200bare auxiliary data. At the outlet, the moonshine should be cold or room temperature, and during fractional distillation, it is separated from the fraction correctly by clean alcohol, the content of sugar in Brage or by smell (the method of experienced vinokurov).

Fastening. The thermometer in the moonshine can be installed at the output of the cube (at the top) or before entering the refrigerator. The second option is preferable, since it allows you to measure the temperature of steam before condensation. But the thermometer in Cuba (the first case) shows the degree of heating of the braga, which is also important. Conclusion: If it is possible, it is advisable to build two thermometers at once.

Thermometers can be put on a cube or in front of the refrigerator

Thermometers can be put on a cube or in front of the refrigerator To install, it is enough to do the hole, the diameter of which coincides with the diameter of the thermometer's setting cylinder (fastening on velcro and plastic retainers are not suitable). On the inside, fix the cylinder bolt and fix the design with a nut. Then insert the thermometer itself.

Attention! When you first start, the homemade moonshine apparatus should be tested by distillation of water, and not immediately pour the braga. Distillation of water is safer, immediately shows problems (if available) and rins all parts of the design well.